Additive manufacturing with FMC/TFM

on 2021-03-01

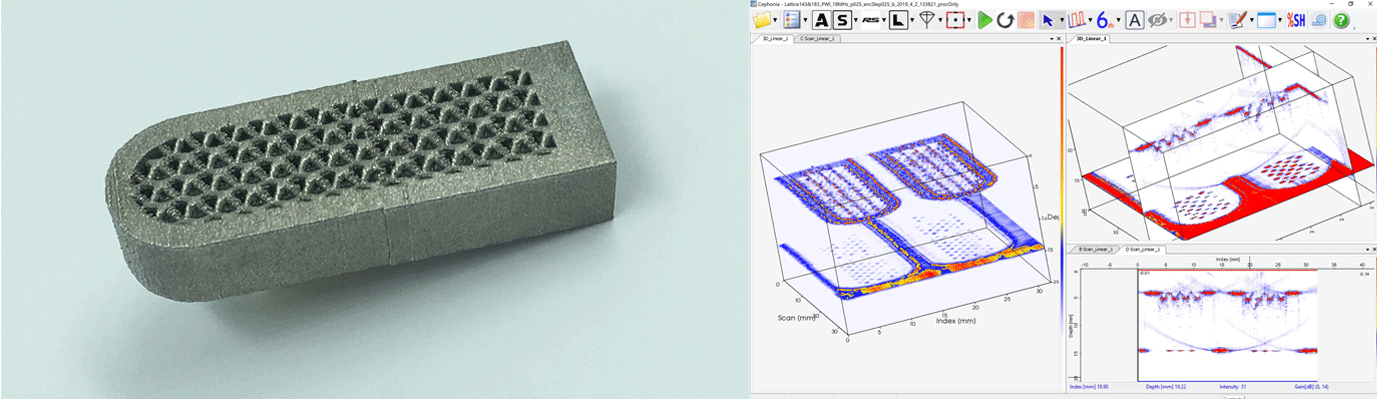

This paper presents the evaluation of two promising non-destructive testing (NDT) methods for the inspection of additively manufactured (AM) parts: a resonant acoustics method (RAM) and a phased array ultrasonic testing (PAUT) method involving a full matrix capture (FMC) acquisition procedure and a total focused method (TFM) to post-process the data and reconstruct the images. The two methods were evaluated using the so-called star artefacts designed in the international standardisation joint group 59 of the ISO/TC261-ASTM/F42 dedicated to NDT for AM parts. These artefacts contain inner and outer features simulating typical AM flaws lying between 100 and 700 μm. The RAM enabled to sort the artefacts with flaws from the reference artefacts without flaw. However, RAM was unable to separate the artefacts according to the number of flaws they contained. The detection with PAUT depended on the shape, orientation and location of the flaws. The best results were obtained for the vertical cylinders, simulating AM cross-layer flaws. They could be detected up to 200 μm

Link: https://link.springer.com/article/10.1007/s40194-020-00932-0